A dive into our product

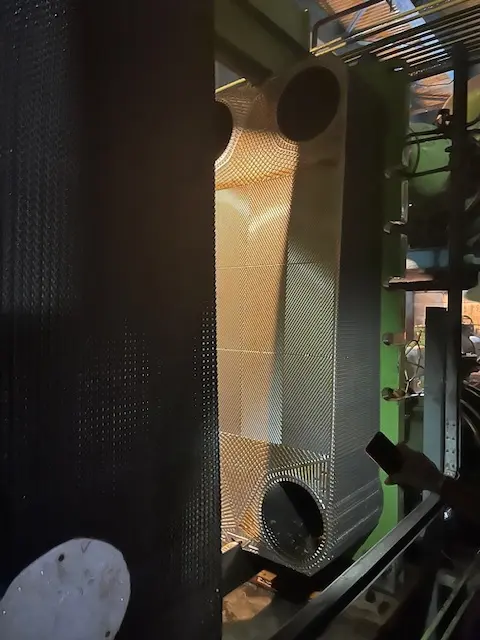

Pittsburgh Chemical Solutions LLC is the patent holder for THERMOPHASE™, a non-biocide/non-hazardous/non-toxic product. THERMOPHASE™ is a nano-coating that prevents fouling and improves thermal efficiency to various heat exchangers such as condensers, chillers, plate and frames, etc.

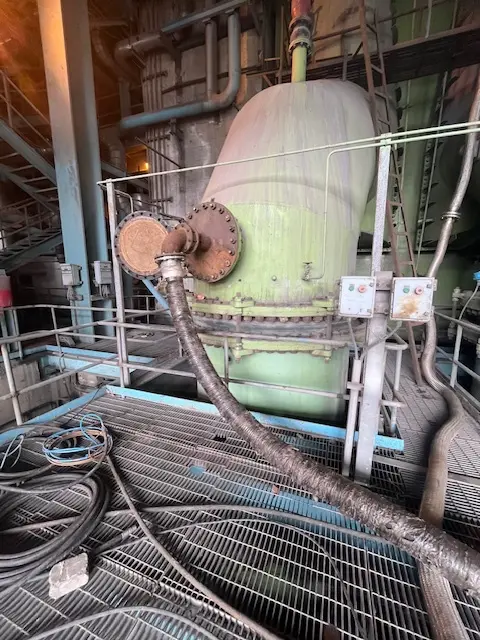

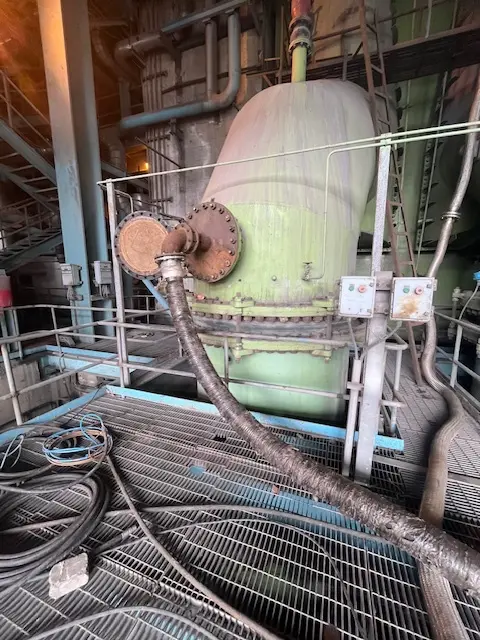

THERMOPHASE™ has installations at hospitals, universities, industrial facilities, and full scale power plants. The amount of THERMOPHASE™ for an application is dependent on the component treated and amount of fluid that it is applied to. The product can be shipped in buckets (small applications), barrels or totes. The THERMOPHASE™ product is an inexpensive and easy applied product that can heavily benefit any facility. Applying to the condenser alone will improve the plant heat rate and provide quick payback.

A recent shipment to a utility in the Midwest was provided for application in their unit's condenser, three closed cooling water heat exchangers, three plate and frame heat exchangers on their vacuum pumps, and application in their 3.3 million water clarifier tank where they were exhibiting MIC.

The evolution of Pittsburgh Chemical Solutions

Interphase Materials Founded

BioInterphase, formally known as Interphase Materials (IPM), was founded in 2015 in Pittsburgh, PA after launching from the University of Pittsburgh. The first technology IPM developed originally created with the intent to reduce biofouling on brain implants to improve neural prosthetic technology.

Awarded Phase 1 Navy SBIR

In 2016, the U.S. Navy awarded IPM a Phase 1 Small Business Innovative Research (SBIR) contract to develop a solution for reducing biological fouling in marine heat exchangers. During the Phase 1 SBIR, IPM created THERMOPHASE™, a biocide-free chemical material that covalently binds to the surface of heat exchanger components to reduce the accumulation of biological organisms.

Awarded Phase 2 Navy SBIR

IPM discovered early during heat transfer testing that THERMOPHASE™ appeared to increase the heat transfer of heat exchangers, even those free from fouling. Due in part to this discovery, the U.S. Navy awarded IPM a Phase 2 SBIR contract in 2017 to continue on the development of THERMOPHASE™.

First Commercial Application on Land-Based Chiller

Following the initial success of the U.S. Navy SBIR development, IPM began transitioning the technology to land-based commercial applications. In 2018, IPM applied THERMOPHASE™ to a land-based chiller plant at the Carnegie Museum of Natural History in Pittsburgh, PA. Since that application, IPM has continued applications to land-based chillers in several states including, Pennsylvania, New York, Illinois, Texas, Nebraska, Massachusetts, and Louisiana.

First Application to a Marine Engine

In 2019, as part of a Phase 3 SBIR awarded by the Rapid Reaction Technology Office, IPM applied THERMOPHASE™ to the seawater cooling system of a Caterpillar engine onboard the M-80 Stiletto. This marked the first time THERMOPHASE™ had been applied to an operating marine system.

First Application to an Operating Powerplant Main Condenser

The following year, the Department of Energy funded IPM to apply THERMOPHASE™ to the first power plant condenser system at the Longview Power Plant in Maidsville, West Virginia. With the support of this project, IPM applied THERMOPHASE™ to the first marine chiller onboard the TS Kennedy using a practical commercial application system.

Biofouling Prevention on Sea Water Cooling System

IPM worked together with the Maritime Administration (MARAD) and Life Cycle Engineering (LCE) to perform this demonstration of THERMOPHASE™ on-board the TS Kennedy at Massachusetts Maritime Academy. This demonstration included coupon testing at key locations in the seawater cooling system, an assessment of the TS Kennedy’s seawater cooled assets and a demonstration application of THERMOPHASE™ to a reefer heat exchanger.

Pittsburgh Chemical Solutions LLC Formed

In late November 2022, Pittsburgh Chemical Solutions LLC is formed, and Interphase Materials licenses THERMOPHASE™ to Pittsburgh Chemical Solutions.

Power Industry Success

Pittsburgh Chemical Solutions doubles THERMOPHASE™ applications in the power industry.

First Large Overseas Order

Pittsburgh Chemical Solutions more than triples THERMOPHASE™ applications in the Power Industry, in addition to gaining the first large overseas order on a power plant. Use of THERMOPHASE™ is also expanded to a hydrogen test facility.

Continued Increased Usage

THERMOPHASE™ installations exceed usage of plants that generate more than 5,000 MW of power generation, and is utilized at a fully integrated paper mill for the first time. Usage of THERMOPHASE™ overseas more than doubles, and THERMOPHASE™ is selected as technology for upcoming application at a nuclear power plant.